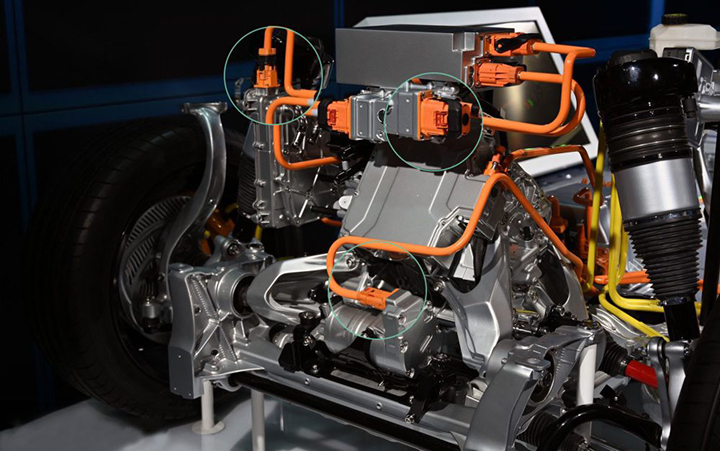

High voltage connector is widely used in electric vehicles. As the link of each functional module of electric vehicles and an essential part of high voltage circuits, it is crucial to analyze and select the types of high voltage connector.

Here is everything you need to know about the type of high voltage connector in Electric Vehicles.

What is High Voltage Connector?

High voltage connector is a functional component that connects the circuit by an electrical signal or mechanical force. It consists of a fixed-end electrical connector (socket) and a free-end electrical connector (plug).

Usually, we classify high-voltage connectors according to their structure, termination method, and installation method.

Structure: terminal, seal, bracket, shell, shielding structure, insulation structure, butt lock structure, positioning structure, high voltage interlock structure, etc.

Termination Method: welding, crimping, screw connection, over-hole connection.

Installation Method: panel type, cable type, nut type, through-wall type.

We generally design the high voltage connectors from the overall and internal structures.

Overall Strctures: Operation space, anti-misoperation structure, connection in place indication, etc.

Internal Structures: Removability of terminals, type, and structure of terminals, etc.

Regarding product performance requirements, high voltage connectors are pretty different from low voltage connectors. Usually, we have higher requirements for electrical performance, mechanical performance, and environmental performance of high voltage connector.

Electrical performance

Electrical properties include operating voltage, rated current, contact resistance of inner and outer conductors, characteristic impedance, voltage standing wave ratio, shielding performance, anti-interference performance, etc.

The electrical performance of high voltage interlocks generally has the following requirements.

- The rated voltage of the high-voltage connector must be greater than the peak voltage of the equipment. Generally need to test the connector’s withstand voltage, insulation resistance, creepage distance, etc..

- The rated current of the high-voltage connector must be greater than the average operating current of the equipment.

Generally need to test the connector’s terminal contact resistance, terminal temperature rise, terminal holding force, cable crimping force, connector locking device strength, etc. - To ensure the safety of the connection of high voltage circuit, we usually add high voltage interlock function to the connector to avoid the potential hidden trouble caused by the disconnection of high voltage circuit.

- In addition, High voltage connectors can be designed with shielding parts to meet 360-degree shielding.

Mechanical performance

Mechanical performance includes vibration shock, mechanical life, single hole separation, total separation force, etc.

Generally, the high voltage connector plugging and unplugging times and connection locking method is reliable to determine whether its mechanical properties meet the requirements.

- As an infrequently disassembled component in electric vehicles, the high voltage connector is generally required to be pluggable more than 50 times.

Environmental performance

Environmental performance includes temperature, humidity, vibration, shock, salt spray, dust, and sealing (water pressure and rain).

- The operating temperature of the high voltage connector must be greater than the sum of the ambient temperature of the equipment and the temperature rise of the terminals when the rated current is passed.

- The most critical impact on the environmental performance of high voltage connector is the IP protection performance. Generally, we take the water tightness test or airtightness test on the connector to test.

- In addition, flame retardant performance is also an important measure to meet the standard.

Types of high voltage connectors (how to choose them)

According to the actual needs of using the high-voltage connector selection, designers must consider a vital issue.

Here we explain the type selection of high voltage connector from three aspects.

Select high voltage connector according to the high voltage system of electric vehicles

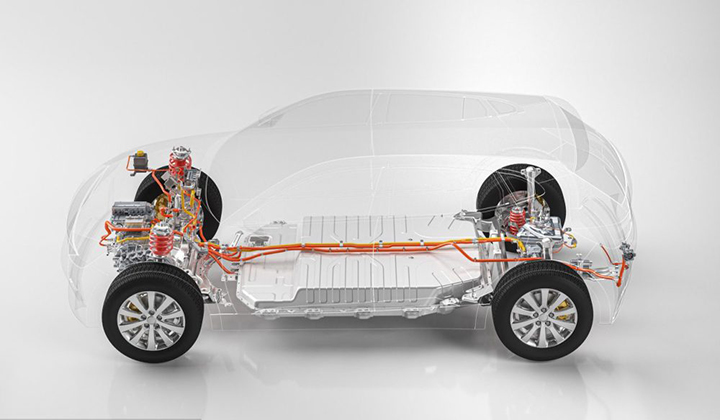

The whole vehicle’s high-voltage system includes power battery, motor/motor controller, PDU, DC or AC charging system, electric heating, electric air conditioning, DCDC, and other electric accessories.

First of all, we need to know the voltage of the entire high-voltage system and the amount of power distribution of each device to determine the load capacity of the high-voltage connector.

Then, according to the layout of the practical electric equipment, determine whether the connectors used are single-core or multi-core.

Here are 4 standard series of high voltage connectors.

1. HVIL 350A Series Connector

In electric vehicles, these high-voltage connectors are mainly used for PDU, Battery, Motor, Motor Controller, etc.

Product parameters

- Rated Voltage:960V AC / 1000v DC

- Rated Current: 350A MAX

- Insulation Resistance: ≥500mΩ

- Wire Range: 50mm²~95mm²

- Mating Cycles: >100

- Positions: 1PIN

- Connection Type: Terminal Machine

- Shell: Zinc alloy

- Terminal: Copper alloy, Silver Plating

2. HVIL 200A Series Connector

This series of high-voltage connectors are mainly used for PDU, Air Condition, Defrosting, Electric Heating, DCDC, etc.

Product parameters

- Rated Voltage:960V AC / 1000V DC

- Rated Current: 200A MAX

- Insulation Resistance: ≥500mΩ

- Wire Range: 25mm²~50mm²

- Mating Cycles: >100

- Positions: 2 POS

- Connection Type: Terminal Machine

- Shell: PA66/Zinc alloy

- Terminal: Copper alloy, Silver Plating

3. HVIL 125A Series Connector

These high-voltage connectors are mainly used for PDU, Battery, Motor, Motor Controller, etc.

Product parameters

- Rated Voltage:960V AC / 1000V DC

- Rated Current:125A

- Insulation Resistance: ≥500mΩ

- Wire Range: 25mm²

- Mating Cycles: >100

- Number of Positions: 2PIN

- Connection Type: Terminal Machine

- Shell: PA66 / Zinc alloy

- Terminal: Copper alloy, Silver Plating

4. HVIL 23A Series Connector

These high-voltage connectors are mainly used for PDU, Air Condition, Defrosting, Electric Heating, etc.

Product parameters

- Rated Voltage:960V AC / 1000V DC

- Rated Current:From 16A to 23A

- Insulation Resistance: ≥500mΩ

- Wire Range: 2.5~4mm²

- Mating Cycles: >100

- Number of Positions: 2 / 3PIN

- Connection Type: Terminal Machine

- Shell: PA66

- Terminal: Copper alloy, Silver Plating

Select high voltage connector according to installation conditions

High-voltage connectors are available in many construction designs designed to meet different installation conditions.

Depending on how the high-voltage harness is lined up on the electric vehicle, we can determine what high-voltage connector is needed.

We can use linear plugs or right-angle plugs to adjust the wire direction of the harness.

Select high voltage connector according to the use environment

After determining the electrical and mechanical properties of the high-voltage connector, we also need to determine whether the environmental performance of connector can meet the actual use of the environment.

The four high-voltage connectors mentioned above have the same environmental performance. They all have excellent water and salt spray resistance levels and HVIL function for most harsh environments.

Below are their specific environmental performance parameters.

- Operating Temperature:-40℃~125℃

- Withstand Voltage: 3500V AC

- Shielding: 360° Shielding

- IP Class: IP67 IP6K9K

- Salt Spray: MAX 96h

- Flammability Rating: UL94 V-0

- HVIL Function: Yes

Summary

High-voltage connector is the blood vessel and nerve of the electrical system of new energy vehicles.

This article introduces and analyzes the selection of high-voltage connectors to improve the vehicle’s reliability and safety performance.

High-voltage connector design is more delicate, structure and performance requirements are high, the future has more excellent development prospects and progress space.

If you have any questions or suggestions, please leave a comment.